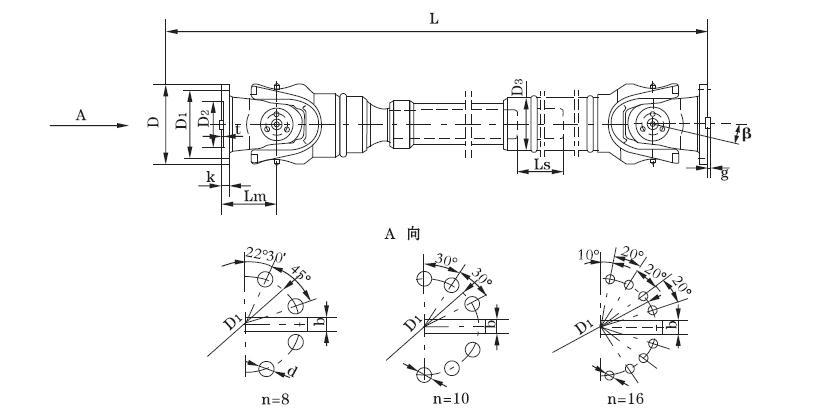

SWC-CH cardan shaftuniversal joint

A universal joint, (universal coupling, U-joint, Cardan joint, Hardy-Spicer joint, or Hooke's joint) is a joint or coupling in a rigid rod that allows the rod to 'bend' in any direction, and is commonly used in shafts that transmit rotary motion.

hiddenValue

- Description

-

General description

A universal joint, (universal coupling, U-joint, Cardan joint, Hardy-Spicer joint, or Hooke's joint) is a joint or coupling in a rigid rod that allows the rod to 'bend' in any direction, and is commonly used in shafts that transmit rotary motion. It consists of a pair of hinges located close together, oriented at 90° to each other, connected by a cross shaft. The universal joint is not a constant velocity joint.

No machine element other than a cardan shaft allows power transmission of torque between specially offset driving and driven shafts whose position can be changed during operation.

Spatial angular motion and changes of axial length are ensured by advanced constructional elements.

Thus, cardan shafts have become an indispensable transmission component in automotive engineering and industry.

Cardan shafts offer

##### » multifunctional application

##### » excellent efficiency

##### » high reliability

##### » low maintenance

##### » easy use

They are an integral part in almost all industries with mechanical drives.

Convince yourself that our products will solve your drive problems to your complete satisfaction.

Selection and use of cardan shafts

Cardan shafts being used for various applications. So it is impossible to select their size and predict their lifetime with reliable accuracy with just one general rule. The familiar failure probabilities for roller bearings apply to cardan shafts as well.

The size of the cardan shaft should be chosen so that its maximum momentary torque rating, is not smaller than the maximum torque to be transmitted in your application. Additionally parameters like deflection angle, speed, length, operating conditions (kind of drive, temperature, dust etc.) should be considered. Therefore please refer to our technical questionnaire. Our experts will evaluate your information given in this questionnaire, to find the best choice for your application. If you need more detailed calculations like determining lifetime, stability etc. please contact us.

Installation instructions

All anti- corrosion paint should be removed carefully from the cardan shaft flanges before the shaft is installed. Anti- corrosion agent on the cardan mounting flanges reduces frictional adhesion (not with flange yokes with staggered tooth arrangement).

Cardan shaft maintenance

It is necessary to grease the moving parts of a cardan shaft at certain intervals to remove used lubricant and foreign matter, if any, and replenishing the lubricant.

Lubrication is required after cleaning with high pressure or a steam jet.

General notes

» The installation of cardan shafts requires expertise and careful workmanship!

» Be sure to follow manufacturer's instructions forinstallation and repair.

» Parts to be installed in universal drives must bein perfect working order and approved for the specific application in hand.

» Make sure that cardan shaft locating centres are properly seated and that the flange surfaces are in perfect contact!

» The operation ratings must never be exceeded.

» Do not use high pressure (water, stream, air) for cleaning to prevent damage of the bearings and sealings!

Specific product description

SWC universal coupling/joint is mainly used in rolling milll,hoisting and other heavy machinery.

Features of SWC series cardan shaft:

1.Gyration diameter:58~620mm

2.Nominal torque:0.15~1000KN*m

3.Max angular misalignment: 25o

4.Reasonable configuration,high safety and long service life

5.High transmission efficiecy:98.6%

CH:long stretch welding type

Type

D

Nominal torque

Tn/

kN·m

Weary torque

f/

kN·m

Angle

β/

(°)≤

LS

Lmin

D1

(js11)

D2

(H7)

D3

Lm

n-d

k

t

b

(h9)

g

Moment of inertia

I/kg·m2

Mass

m/kg

Lmin

Increase per 100mm

Lmin

Increase per 100mm

SWC180CH1

180

12.5

6.3

25

200

925

155

105

114

110

8-17

17

5

-

-

0.181

0.007

74

2.8

SWC180CH2

700

1425

0.216

104

SWC225CH1

225

40

20

15

220

1020

196

135

152

120

8-17

20

5

32

9

0.561

0.0234

132

4.9

SWC225CH2

700

1500

0.674

182

SWC250CH1

250

63

31.5

15

300

1215

218

150

168

140

8-19

25

6

40

12.5

1.016

0.0277

190

5.3

SWC250CH2

700

1615

1.127

235

SWC285CH1

285

90

45

15

400

1475

245

170

194

160

8-21

27

7

40

15

2.156

0.051

300

6.3

SWC285CH2

800

1875

2.36

358

SWC315CH1

315

125

63

15

400

1600

280

185

219

180

10-23

32

8

40

15

3.812

0.0795

434

8

SWC315CH2

800

2000

4.15

514

SWC350CH1

350

180

90

15

400

1715

310

210

267

194

10-23

35

8

50

16

7.663

0.2219

672

15

SWC350CH2

800

2115

8.551

823

SWC390CH1

390

250

125

15

400

1845

345

235

267

215

10-25

40

8

70

18

12.73

0.2219

817

15

SWC390CH2

800

2245

13.617

964

SWC440CH1

440

355

180

15

400

2110

390

255

325

260

16-28

42

10

80

20

22.54

0.4744

1312

21.7

SWC440CH2

800

2510

24.43

1537

SWC490CH1

490

500

250

15

400

2220

435

275

325

270

16-31

47

12

90

22.5

33.97

0.4744

1554

21.7

SWC490CH2

800

2620

35.87

1779

SWC550CH1

550

710

355

15

500

2585

492

320

426

305

16-31

50

12

100

22.5

72.79

1.357

2585

34

SWC550CH2

1000

3085

79.57

3045

keywords:- SWC-CH cardan shaftuniversal joint

- shaft u joint

- hooke\'s joint

- universal joint for drive shaft

- motor coupling

Recommend

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!