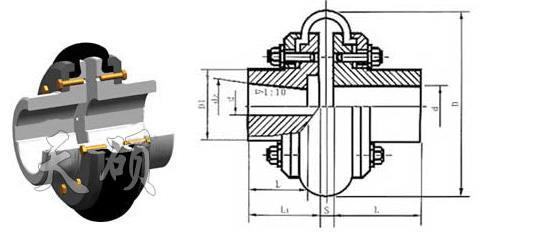

OMEGA tyre coupling

Tanso tyre couplings requires no lubrication prompting cleanliness that is especially desirable in such fields as food processing and textiles hence requiring no periodic maintenance as a result.

hiddenValue

- Description

-

Features:

1. Acts as Self-Aligning Agent

2. Avoids Metal Contact

3. Smoothness Vibration

4. Gives Life to Bearings

5. Removes Unpleasant Sound

6. Takes End Level Shock Load

7. Makes Easy Replacement

8. Suits to Vertical Drive

9. Avoids Cost Against Breakdown

10. Decreases Temperature Rise

Cushion Shock Loads

It cushions Shock Loads and absorbs Torsional and Lateral Vibration real enemies of valuable machines. Vibrations that could produce undesirable sounds are also isolated. Transmission of gear noise and motor hum between shafts is reduced. Tanso tyre coupling provides just a steady constant dampening effect regardless of the direction of rotation and protects system components from fatigue failure.

No Lubrication or Maintenance

Tanso tyre couplings requires no lubrication prompting cleanliness that is especially desirable in such fields as food processing and textiles hence requiring no periodic maintenance as a result.

Simplified Design

No gears • No seals • No bearings • No wearing parts • No backlash clearance. Tanso tyre coupling forms one combined assembly, there is no relative movement inside of any part.

Easy Installation

Quick and Easy to install • No need for precise Shaft Alignment

Initial assembly of the Tanso tyre coupling is a simple operation. Alignment may be roughly checked by placing accurate measuring equipment, since small errors in misalignment are easily, accommodated by the Resilient Member. To replace the Flexible Member, simply loosen the Bolts, remove the Tyre and replace with a new one. It is not necessary to move either the driving or driven machines during the entire operation. The split Flexible Member is placed so that bearing on both sides is held between the Flanges and the Clamping Rings. The bolts are then tightened into place to grip the Resilient Member fully.

Safety

No metal to metal contact between two shafts, therefore. the cushion coupling insulates against flow of current from one shaft to the other No sharp edges, metal surfaces are finished all over.

Specific product description

Type

Dimensions(mm)

Bolt amount

Md×LBore diameter

Bore length

Torque

Speed

Moment of inertia

Mass

D

D1

S

d dz

L

L1

Tn

[n]

kg.m2

kg

Y J1

Z1

N.M

r/min

LLA1

60

20

4

12-M4×10

6-11

16-25

-

10

5000

0.0004

0.35

LLA2

100

36

8

12-M6×20

8-19

14-42

35

20

5000

0.005

1.33

LLA3

135

48

12

12-M8×25

18-28

30-62

35-50

80

4000

0.022

3.4

LLA4

180

64

18

12-M10×30

25-38

44-82

50-65

160

3150

0.071

7.4

LLA5

210

80

18

16-M10×40

32-50

60-112

65-90

315

2800

0.154

13.4

LLA6

265

100

24

16-M12×40

40-56

84-112

90

630

2500

0.46

22.6

LLA7

310

120

28

16-M16×50

48-75

84-142

90-120

1250

2000

1.86

34.8

LLA8

400

150

38

16-M20×60

60-95

107-172

120-145

2500

1600

3.57

74.3

LLA9

450

190

42

20-M20×70

80-125

132-212

145-180

500

1250

6.47

111

LLA10

550

230

52

24-M24×80

100-150

167-252

180-220

10000

1000

17.55

191

LLA11

700

280

70

32-M30×90

130-180

202-302

220-270

20000

800

54.1

373

keywords:- tyre coupling

- flexible shaft coupling

- flexible tyre coupling

- types of shaft couplings

- coupling sleeve

- shaft connector

Recommend

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!