Z19 type locking device

Tanso Shaft Locking Devices connect hubs solidly to shafts, using a keyless mechanical interference fit, to transmit torque or to withstand axial thrust.

hiddenValue

- Description

-

Tanso Shaft Locking Devices connect hubs solidly to shafts, using a keyless mechanical interference fit, to transmit torque or to withstand axial thrust. This mechanical interference fit utilizes screw tension in the Shaft Locking Device, converted into radial pressure via an inclined plane. This pressure expands the Shaft Locking Device to eliminate the gap between the hub and the shaft. The Shaft Locking Device uses the friction bond between the Shaft Locking Device and the shaft/hub to create a zero backlash connection. This connection is easily releasable to remove the mechanical interference fit.

Tanso Shaft Locking Devices expand to fill the gap between the shaft and hub, allowing for easy installation and removal, saving time over traditional interference fit techniques. The contact pressures created using a Shaft Locking Device can be greater than traditional interference fit pressures, allowing for more torque to be transmitted or shorter hubs to be used. The easy installation also allows the hub to be positioned more accurately on the shaft, and can facilitate angular timing of the hub.

Easy assembly and disassembly

Both actions take place by locking and unlocking the clamping screws with common tools.

The use of a torque wrench is only necessary when a more precise torque is required.

Superior holding power

The action of the clamping cones creates shaft clamping torque superior to a normal keyed hub.

Overload protection

When the pre-set torque is exceeded locking device will slip, preventing the connected elements from being broken.

Note: Locking units are not friction couplings, so excessive slip will cause damage.

Easy adjustment

Combining the locking device design of smooth cone action with superior holding power, the hub can be clamped at any position along a shaft, eliminating the need for lock washers, spacers , stop rings, etc.

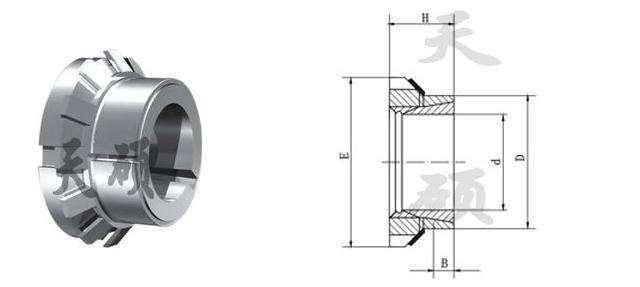

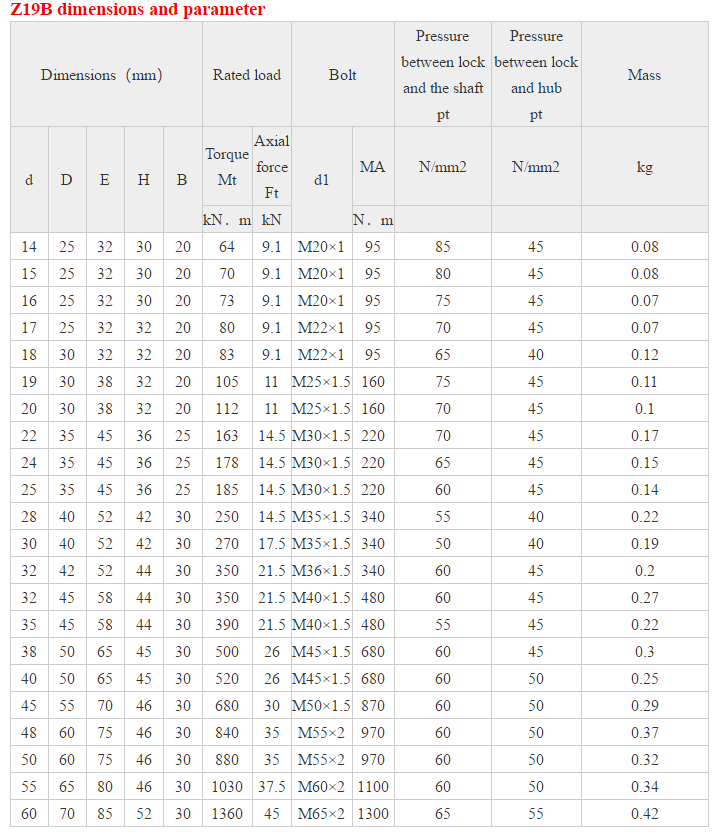

Specific product description

Consists of two tapered rings and a lock nut.In virtue of the simple design,very fast assembly/disassembly is allowed.Z19 is suitable for applications with small-medium torque.

Z19A dimensions and parameter

Dimensions(mm)

Rated load

Bolt

Pressure between lock and the shaft

pt

Pressure between lock and hub

pt

Mass

d

D

E

H

B

Torque

Mt

Axial force

Ft

d1

MA

N/mm2

N/mm2

kg

kN.m

kN

N.m

14

25

32

16.5

6.5

38

5.1

M20×1

95

200

110

0.05

15

25

32

16.5

6.5

41

5.5

M20×1

95

185

110

0.04

16

25

32

16.5

6.5

43

5.45

M20×1

95

174

110

0.04

17

26

32

16.5

6.5

47

5.5

M20×1

95

164

107

0.04

18

26

32

16.5

6.5

49

5.4

M22×1

95

155

107

0.04

18

30

38

16.5

6.5

58

6.6

M25×1.5

160

185

112

0.06

19

30

38

18

6.5

62

6.6

M25×1.5

160

176

112

0.06

20

30

38

18

6.5

66

6.6

M25×1.5

160

167

111

0.06

22

32

38

18

6.5

73

6.6

M25×1.5

160

152

105

0.06

24

35

45

18

6.5

105

8.75

M30×1.5

220

185

127

0.08

25

35

45

18

6.5

110

8.8

M30×1.5

220

178

127

0.07

28

36

45

18

6.5

120

8.55

M32×1.5

220

159

124

0.06

28

40

52

18

6.5

149

10.6

M35×1.5

340

188

141

0.09

30

40

52

19.5

7

160

10.6

M35×1.5

340

164

123

0.09

32

42

52

19.5

7

170

10.6

M36×1.5

340

154

117

0.09

35

45

58

21.5

8

230

13.1

M40×1.5

480

153

120

0.11

36

45

58

21.5

8

240

13.3

M40×1.5

480

149

120

0.1

38

48

58

21.5

8

250

13.1

M42×1.5

480

141

112

0.12

38

50

58

21.5

8

250

13.1

M42×1.5

480

141

112

0.14

40

50

65

24.5

10

310

15.5

M42×1.5

680

124

93

0.14

40

52

65

24.5

10

310

15.5

M45×1.5

680

120

93

0.17

42

55

65

25.5

10

320

15.2

M48×1.5

680

114

87

0.2

45

55

70

25.5

10

400

17.7

M50×1.5

870

122

96

0.16

45

57

70

25.5

10

400

17.7

M50×1.5

870

122

96

0.2

48

60

75

25.5

10

500

20.8

M55×2

970

135

105

0.21

50

60

75

25.5

10

520

20.8

M55×2

970

130

105

0.18

50

62

75

25.5

10

520

20.8

M55×2

970

130

105

0.22

55

65

80

27.5

12

610

22

M60×2

1100

103

84

0.21

55

68

80

27.5

12

610

22

M60×2

1100

103

84

0.28

56

68

80

27.5

12

620

22

M60×2

1100

101

82

0.26

60

70

85

30

12

800

26.6

M65×2

1300

113

93

0.24

60

73

85

30.5

12

800

26.6

M65×2

1300

113

93

0.33

63

79

92

30.5

14

980

31.1

M70×2

1600

107

86

0.43

65

79

92

30.5

14

1010

31

M70×2

1600

104

86

0.38

70

84

98

31.5

14

1240

35.4

M75×2

2000

110

92

0.42

keywords:

keywords:- type locking device

- shaft locking

- joint shaft axle wheel

- keyless shaft-hub locking device

- locking assembly

Recommend

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!