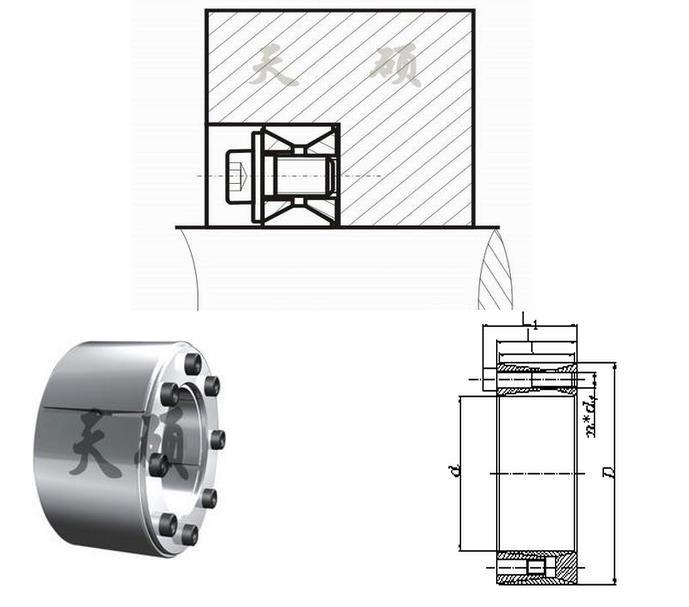

Z4 type locking device

Tanso Shaft Locking Devices connect hubs solidly to shafts, using a keyless mechanical interference fit, to transmit torque or to withstand axial thrust.

hiddenValue

- Description

-

Tanso Shaft Locking Devices connect hubs solidly to shafts, using a keyless mechanical interference fit, to transmit torque or to withstand axial thrust. This mechanical interference fit utilizes screw tension in the Shaft Locking Device, converted into radial pressure via an inclined plane. This pressure expands the Shaft Locking Device to eliminate the gap between the hub and the shaft. The Shaft Locking Device uses the friction bond between the Shaft Locking Device and the shaft/hub to create a zero backlash connection. This connection is easily releasable to remove the mechanical interference fit.

Tanso Shaft Locking Devices expand to fill the gap between the shaft and hub, allowing for easy installation and removal, saving time over traditional interference fit techniques. The contact pressures created using a Shaft Locking Device can be greater than traditional interference fit pressures, allowing for more torque to be transmitted or shorter hubs to be used. The easy installation also allows the hub to be positioned more accurately on the shaft, and can facilitate angular timing of the hub.

Easy assembly and disassembly

Both actions take place by locking and unlocking the clamping screws with common tools.

The use of a torque wrench is only necessary when a more precise torque is required.

Superior holding power

The action of the clamping cones creates shaft clamping torque superior to a normal keyed hub.

Overload protection

When the pre-set torque is exceeded locking device will slip, preventing the connected elements from being broken.

Note: Locking units are not friction couplings, so excessive slip will cause damage.

Easy adjustment

Combining the locking device design of smooth cone action with superior holding power, the hub can be clamped at any position along a shaft, eliminating the need for lock washers, spacers , stop rings, etc.

Specific product description

It is suitable for high torque and is self-centering.Rcommened for applications tha requirs high transmission values and excellent centering capabilities such as belt drums.

Feature:

1.Heavy duty, external shaft locking device

2.Very high torque

3.Self-centering

4.Exceptional concentricity

installition

Dimensions

Rating load

Pressure between lock and shaft

pr

N/mm2Pressure between lock and hub

pr

N/mm2Tightening torque MA

N.mMass

kgd

D

l

L

L 1

d 1

n

Axial force Ft

kNTorque Mt

kN. m( mm )

70

120

56

62

74

M12

8

197

6.85

201

117

145

3.3

80

130

12

291

11.65

263

162

3.7

90

140

290

13.00

234

150

4.0

100

160

74

80

94

M14

15

389

19.70

213

133

230

7.2

110

170

483

22.60

242

157

7.7

120

180

482

28.90

222

148

8.3

125

185

480

30.00

212

143

8.5

130

190

31.20

205

140

8.8

140

200

18

574

40.20

227

159

9.3

150

210

572

42.90

212

152

10.0

160

230

88

94

110

M16

800

64.00

227

158

355

14.9

170

240

795

67.80

214

152

15.7

180

250

21

923

83.00

235

170

16.4

190

260

921

88.00

223

163

17.2

200

270

24

1050

105.00

242

179

18.8

210

290

110

116

134

M18

20

1118

117.30

197

143

485

23.0

220

300

21

1120

123.00

189

138

27.7

240

320

24

1280

153.00

198

148

29.8

250

330

27

1282

160.20

205

157

31.0

260

340

1430

186.00

157

32.0

280

370

130

136

156

M20

24

1650

230.00

192

145

690

46.0

300

390

245.00

179

138

49.0

keywords:- type locking device

- power lock

- keyless locking device

- shaft locking assemblies

- clamp power locks

- safe locking device

Recommend

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!