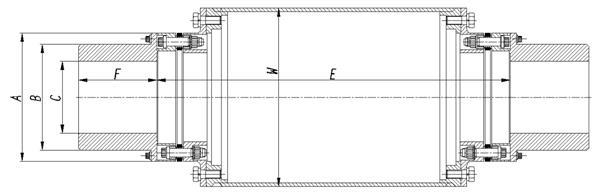

TACF disc coupling

Disc coupling: by definition, transmits torque from a driving to a driven bolt tangentially on a common bolt circle.

hiddenValue

- Description

-

Disc coupling: by definition, transmits torque from a driving to a driven bolt tangentially on a common bolt circle. Torque is transmitted between the bolts through a series of thin, stainless steel discs assembled in a pack. Misalignment is accomplished by deforming of the material between the bolts.

A disc coupling is a high performance motion control (Servo) coupling designed to be the torque transmitting element (by connecting two shafts together) while accommodating for shaft misalignment. It is designed to be flexible, while remaining torsionally strong under high torque loads. Typically, disc couplings can handle speeds up to 10,000 RPM.

There are two different styles of disc coupling:

Single Disc Style couplings are composed of two hubs (the ends of the coupling, which are typically made from aluminum, but stainless steel is used as well) and a single, flat, stainless steel disc spring

Double Disc Style coupling is also composed of two hubs, but has an additional center spacer sandwiching two disc springs. The center spacer can be made out of the same material as the hubs, but is sometimes available in insulating acetal, which makes the coupling electrically isolating.

The difference between the two styles is that single disc couplings cannot accommodate parallel misalignment due to the complex bending that would be required of the lone disc. Double disc styles allow the two discs to bend in opposite directions to better manage parallel offset. The discs are fastened to the hubs (and center spacer on double disc styles) with tight fitting pins that do not allow any play or backlash between the disc and the hubs. The discs can be bent easily and as a result, disc couplings have some of the lowest bearing loads available in a motion control coupling.

Torsionally stiff and still flexible, disc couplings are a great solution for high speed applications. The downside is that they are more delicate than the average coupling and can be damaged if misused. Special care should be taken to ensure that misalignment is within the ratings of the coupling.

Advantages of disc coupling

1. Eliminates the need for lubrication and coupling maintenance

2. Coupling can be inspected without disassembly

3. Condition of disc packs can be inspected with a strobe light while the machine is running

4. Note: It is not recommended that couplings be operated without coupling guards.

5. Easy to assess equipment misalignment

6. Torsionally rigid without any backlash

7. No wearing parts

8. Resistance to harsh environments

9. Long life when properly sized and aligned

10. High power density (higher torque for a given outside diameter)

Model NO.

Power/Speed

(Kw/rpm)

Nominal torque

(KNm)

Peak torque

(KNm)

A

(mm)

B

(mm)

C max (mm)

F

(mm)

Wmin

(mm)

W available sizes

20#(seamless sleeve)

W available sizes

Q235-B(spiral sleeve)

TACF8363

6.6

63

140

365

260

195

200

244

426x12

508x10,457x10

TACF8396

8.5

81.11

197

398

280

210

215

272

------

529x10,508x10,457x10

TACF8425

11

105

217

427

294

220

230

272

------

630x10,529x10,508x10,457x10

TACF8457

14

133.7

320

459

322

240

240

298

------

630x10,529x10,508x10,457x10

TACF8493

17

162.3

355

495

352

260

260

324

------

720x10,630x10,529x10,508x10,457x10

TACF0537

25

238.75

548

539

374

275

280

350

------

720x10,630x10,529x10,508x10,457x10

TACF0580

35

334.25

770

582

415

300

305

350

------

720x10,630x10,529x10,508x10,457x10

keywords:- disc coupling

- diaphragm coupling,

- membrane coupling

- coupling manufacturer

- sleeve coupling

- steel coupling

Recommend

Get quotes

Note: Please leave your email, our professional staff will contact you as soon as possible!